We Make Magic With Metal.

There’s a revolution happening, and it’s made of liquid metal. At LQDX (‘lik-WID-ix) we’re setting a new standard in metal deposition with our breakthrough family of precision Liquid Metal Inks®. Any 3D surface can now be metalized, atom-by-atom, using a simple, liquid-based application, enabling previously impossible circuitry and catalyst products to be built with unprecedented affordability. Artificial Intelligence has created a seismic shift in tech, and LQDX is meeting the challenge head on.

Liquid Metal Ink.®

The Future Of Precision Metal Deposition.

Invented at the legendary Stanford Research Institute and engineered at LQDX’s Silicon Valley labs, our patented family of organic liquid metals enables nanoscale layers of pure palladium, gold or copper to be applied to a wide array of substrate materials with unparalleled coverage, conformality and reliability. Green, non-toxic and bio-compatible, our revolutionary inks will empower the creation of breakthrough products in Life Sciences, Clean Energy and Advanced Semiconductors.

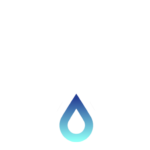

Supercharging The AI Interconnect Revolution.

AI is driving innovation at a rate of change the world has never seen before. It’s overwhelming existing supply models, and new material and process tools are urgently needed in the industry toolbox. When it comes to interconnect—the critical circuitry that links the array of silicon chips to each other and their final systems—a quantum reduction in circuit size is needed, while increasing data speed and reducing system cost. Liquid Metal Ink® (LMIx®), a disruptive leap in interconnect technology, is rewriting the rules of circuit design and manufacturing. Imagine depositing metal, atom-by-atom, to create tailorable nanoscale patterns 100x denser than what’s been possible before. It may sound like science fiction, but it’s not.

Find Your Liquid-X.

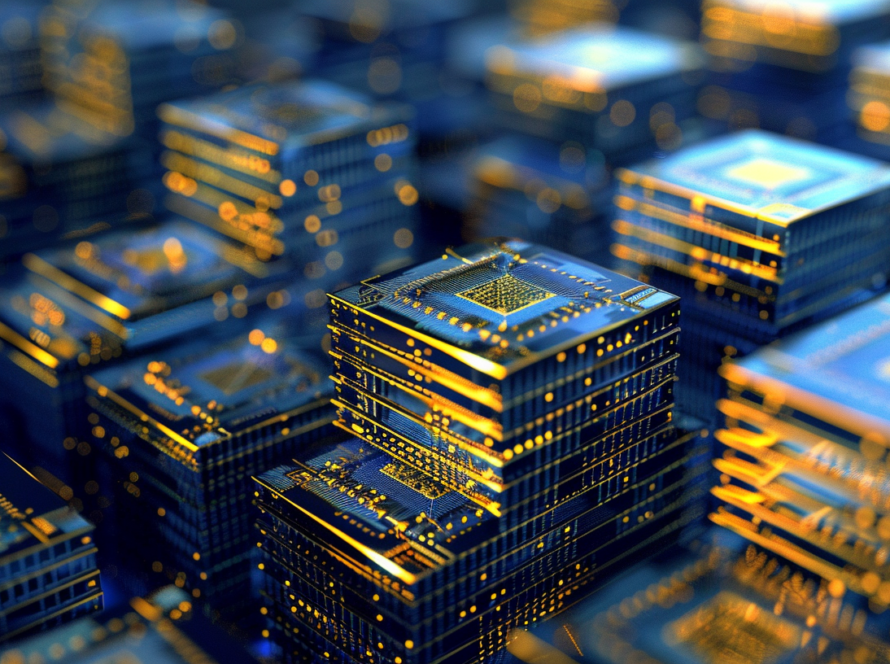

1um and Beyond.

The Road To Sub-Micron Interconect.

LQDX has developed a technology platform that meets the unprecedented demands of the semiconductor roadmap for the next 10 years. From ultra-dense IC-substrates, to complex multi-layer interposers and advanced wafer-level fan-out techniques, LQDX has a tried and tested solution. Our years of work on advanced government contracts and stealth programs have prepared us for this moment. So when the industry asks “what’s next?” we already have the answer. The future of interconnect belongs in the sub-micron realm, and that’s the LQDX sweet spot.

What Do You Want To Build With LMIx® ?

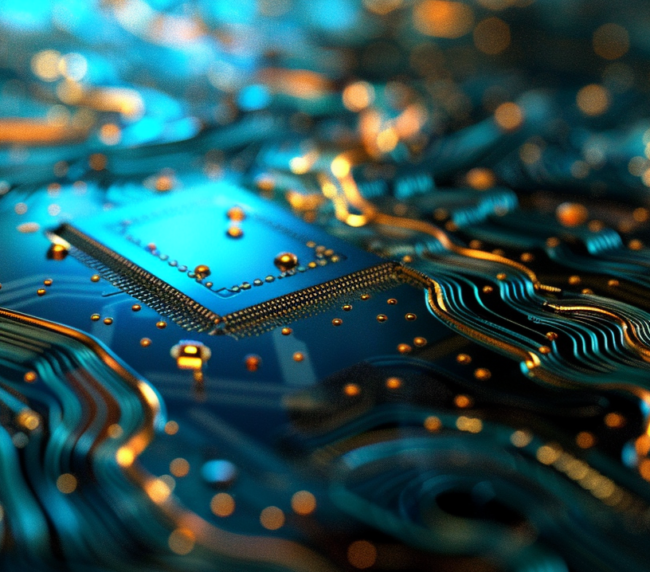

Smaller, Faster, Cheaper.

Gordon Moore, co-founder of Intel, predicted in 1965 that computing power would double every two years, driving exponential growth in capability and intelligence. “Moore’s Law” has governed the growth of computing since and become synonymous with the mantra “Smaller, Faster, Cheaper.” 60 years later, Moore’s Law is advancing in three dimensions—where chips are stacked like skyscrapers, single chips are divided into “chiplets” with specific optimized tasks. Everything is linked together using advanced interconnect and semiconductor packaging techniques. This is where LQDX shines—our revolutionary liquid metal deposition technology ties all the building blocks of this new architecture together in the smallest, fastest and most cost effective way possible.

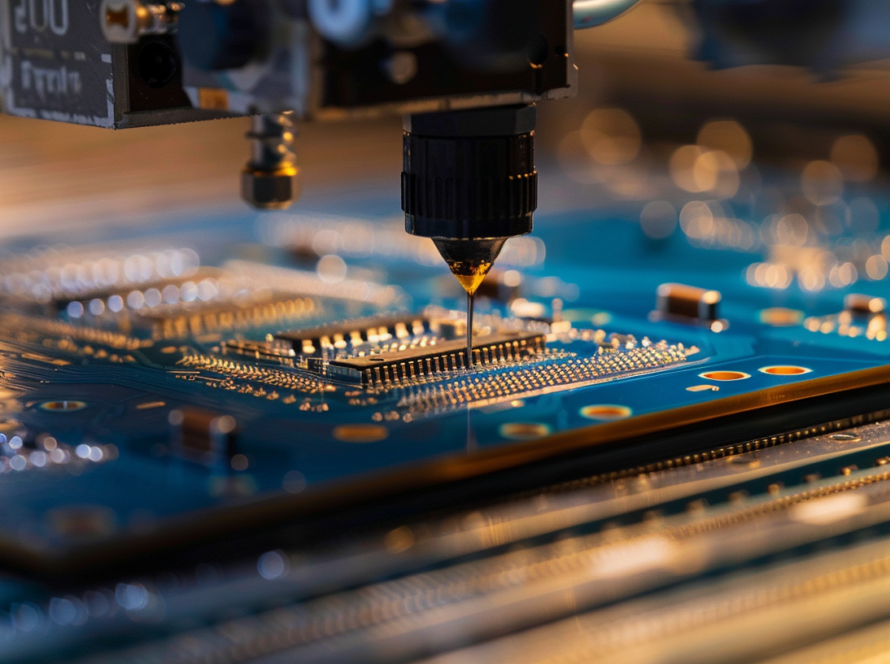

Why Liquids?

Cost effective. Easy to integrate into the production process.

It’s essential to be smaller (enabling the highest circuit density), it’s vital to be faster (to support the remarkable data-processing speeds), but it’s also crucial to be cheaper (otherwise the architecture is too costly to implement). This is the power of liquid deposition over vacuum methods. Vapor Deposition, either Physical “PVD” or Chemical “CVD”, relies on expensive process equipment typically used for wafer manufacturing, at 10X the cost of a simple liquid application. LQDX’s PVD-in-a-BottleTM solution remedies this, allowing our customers to create the cutting-edge products they need without having to rebuild their factory infrastructure at 10X the cost. A simple dip or spray is all that is needed.

Discover The Liquid-X Process That Is Right For You.

We Serve Multiple Markets.

Semiconductor / Packaging

Our latest Liquid Metal Inks (LMIx® ) are meticulously formulated to facilitate every level of Heterogeneous Integration.

Medical Devices

Our biomedical compliant materials are facilitating the creation of Class One, Class Two and Class Three medical devices.

Hydrogen Catalysis

From Fuel Cells to Electrolyzers, our PGM inks enable the creation of electrodes to power the Hydrogen revolution.

Advanced PCB

Our inks have been enabling advanced PCB makers to create cutting-edge, high-speed products with ultra fine circuits.